Portable Power Box

A few years ago for camping I wanted a box to hold a huge battery (12v 90Ah) so we had power for the whole week. This was for various items, mainly lighting and charging phones. However this box quickly became one of the focal points of the trips for everyone that had something to charge, be it a phone, camera or anything else.

To begin with, I decided what we needed in terms of power. At the moment we had a 4 socket cigarette lighter splitter which we could plug numerous devices into. We also had a plug in USB charger which we burned out with a few days of the trip left. This of course wasn’t very good so we need a new solution to that. I also had a digital multi meter for monitoring the battery state of charge which was bulky and unnecessary, so a solution for that was also needed.

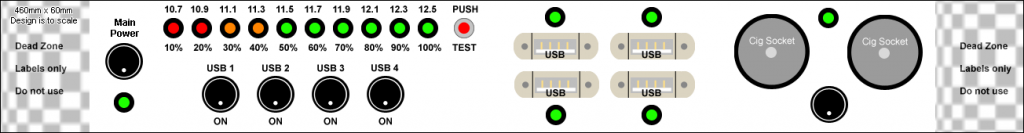

After careful consideration I decided on having 2 cigarette lighter sockets, 4x 1A USB sockets and an LED bar-graph style volt/state of charge meter. Each of the USB sockets will be powered separately and both cigarette lighter sockets will be on at once. The volt meter will be either push to make, release to break or push to make and push to break. As it turns out the switch I chose could do both depending on the pressure you put upon it.

USB and LED Volt Meter

After I decided on the specifications, I had to decide how I was going to make the USB ports and the LED volt meter.

For the USB ports I initially wanted to use the very simple and very cost effective LM7805 5v 1.5A regulator as this made everything very simple. However it turned out that these were simply too inefficient and got extremely hot without a massive heat sink to take away the heat. This made it infeasible to use. I needed another solution.

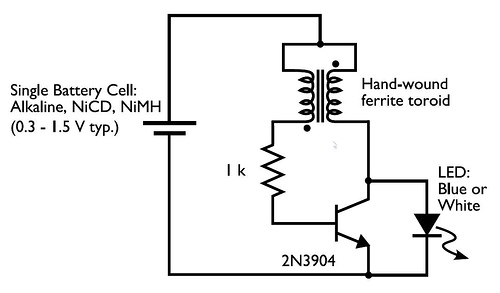

Eventually I found the LM2575, which is a switched mode 5v 1A regulator. This required additional external circuitry which was hard to find and a little expensive, but once built I realised how much more efficient it was. Virtually no heat was emitted from the regulator or the inductor that I had to use. The efficiency must easily have doubled. After careful planning and testing I eventually made the final board which is now used in the final product.

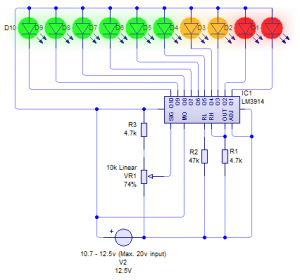

Having operated solar equipment for years I knew the voltage range I needed for the volt meter to work in order to understand the chemistry of the battery and it’s state of charge. This range is 10.5v (totally flat battery) to 12.6v (100% full battery while resting with no surface charge). As the driver works with 10 LED’s I decided on 2 red, 2 orange and 6 green LED’s with 0.2v separation between each. The scale would begin at 10.7v and go up to 12.5v which would indicate a 10%-100% state of charge (while resting).

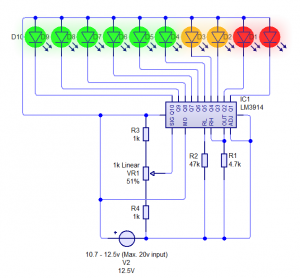

The LM3914 was a pain to get it to work. The documentation to me isn’t overly clear and it took weeks to get it working, but eventually I found a plan online to go by and now it works perfectly, though to be honest the 10k POT could do with changing to a 1k POT with a 1k either side of it. It’s a bit sensitive to changes in my design. Below are both designs so you can choose which to use.

Right: Modified POT/resistors values for less sensitivity and more accurate adjustment

This circuit works for a variety of ranges but the minimum and maximum values are around 2.0-2.5v from each other depending on your voltage range. You will need to experiment. For 10.7-12.5v the value from minimum to maximum is about 2.0v. The potentiometer adjusts it. To set it up, set your voltage to 12.5v and turn the potentiometer until the final LED just lights up. Now set it to 10.7v and it should extinguish all but the final LED. It’s not 100% accurate but it’s a very good representation and that’s all I needed for this project. If you want accuracy, buy a digital volt meter instead.

The Front Panel

Once the two hardest electronics parts were out of the way I set about with the front panel design. This along with knowing the battery dimensions and other items that were going into the box, allowed me to set a size for the box itself. This part is entirely up to you to set based on your battery and other components including your front panel design.

I first set out on paper but quickly realised this was hard when mistakes were made. In the end I switched to Photoshop and used exact size measurements of my components. This is great when using Photoshop as you can also print to the same size onto paper and it remains accurate. This was the key to making my front panel. I measured each component and made a graphic in Photoshop, duplicating where needed to make my layout. Below is my final panel design. All graphics were created by myself in Photoshop but you can feel free to copy.

When making the front panel itself, I quickly realised the USB ports weren’t going to fit correctly, so I used some 1.6mm thick plastic to mount them instead. The wood panel behind had a hole cut in with some overlap for the plastic to be fastened with nuts and bolts. This allowed for a cleaner look and for the plugs to fit into the sockets cleanly with a good connection.

The soldering of the parts was a major problem for me. I ended up ordering a new soldering iron as my little 15w iron wasn’t up to the job. One mistake I made was trying to solder to the tabs on the switches. Don’t do this, you’ll only ruin your switches as I did by melting them. Instead get some push on crimped connectors instead and use those. I melted 4 switches in an attempt to solder to them so it’s not worth the risk or the money.

Always remember to heat shrink tube your connections to avoid short circuit where you can, and most definitely don’t forget to use a fuse! I used a 15A fuse which should be plenty to include draw from the cigarette sockets. Remember to carry spare fuses too!

The Final Product

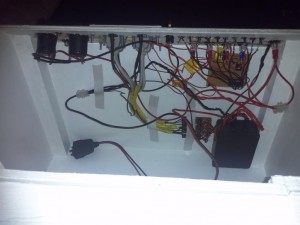

Here is the final product. It’s by no means perfect, the wiring is awful and there are cosmetic defects, but this was my first try and it came out better than I expected. For that reason, I’m happy enough!

Future additions will be the power inverter and some carry handles as it’s 30KG in weight!

The finished product

Images of the inside with the battery and the electrics (messy!)

Click the images to enlarge